Date: 06 Aug, 2025

Industrial processes in many manufacturing sectors still rely on outdated, manual systems that hinder efficiency, limit scalability, and increase operational costs. The lack of real-time data, automation, and connectivity often leads to production delays, high waste, and poor resource utilization. DesignX addresses this challenge through its digital platform, Df-OS (Digital Factory Operating System), which integrates hyper-automation, IIoT, and AI to streamline operations, enhance visibility, and drive data-driven decision-making across factory floors. By enabling seamless digitization without the need for extensive infrastructure changes, DesignX is redefining how factories operate in the digital age.

About DesignX

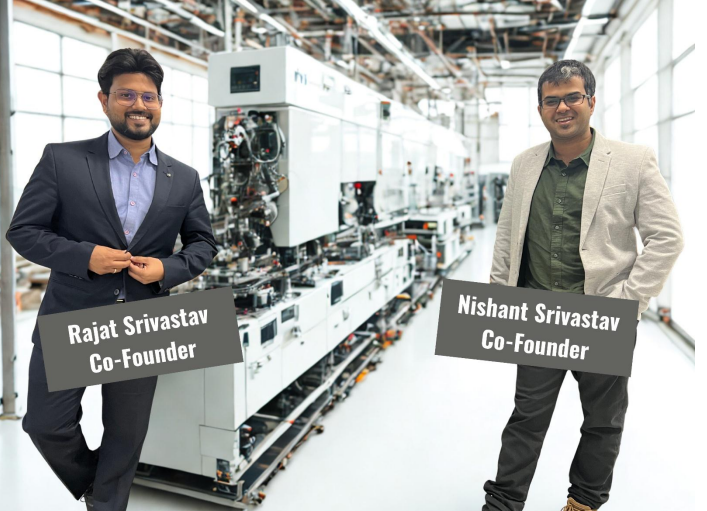

Founded in 2015 by engineer brothers Rajat and Nishant, DesignX is building the Digital Factory Operating System (Df-OS), a unified platform designed to enable end-to-end digitization of factory operations. Df-OS empowers manufacturers to modernize without disrupting existing infrastructure by seamlessly connecting machines, processes, and people. Unlike traditional IoT platforms, Df-OS focuses on frontline workforce empowerment and deep process integration, helping manufacturers eliminate inefficiencies, enhance real-time visibility, and drive scalable transformation across their operations.

Df-OS: Scalable, Modular, and Built for Frontline Impact

Df-OS focuses on frontline empowerment and deep process integration, going beyond traditional IoT platforms. Unlike hardware-bound solutions, Df-OS integrates easily with any existing systems (ERP, SCADA, IoT) and is preloaded with 600+ use-case apps. Its lightweight, modular design makes it highly scalable and cost-efficient, creating stickiness for enterprise clients by solving complex pain points like supplier quality tracking, traceability, and sustainability reporting .

Holistic Defensibility

While many industrial digitization solutions focus narrowly on asset connectivity, analytics, or specific use cases such as anomaly detection or production monitoring, DesignX takes a more comprehensive approach. Its Digital Factory Operating System (Df-OS) serves as a fully customizable, end-to-end platform that integrates all aspects of shopfloor operations into a unified digital ecosystem. What sets it apart is its flexibility allowing deployment across diverse industrial environments without heavy infrastructure overhauls and its ability to scale from individual machines to entire factory networks. Unlike tools that offer only point solutions or limited visibility, Df-OS provides deep, system-wide integration that supports everything from real-time monitoring and predictive insights to workflow automation and operational optimization.

Industry Landscape

Industry Landscape

The global smart manufacturing software market is projected to grow from US$124 billion in 2024 to US$359 billion by 2032, driven by advancements in IoT, 5G, AI, and big data integration. In India, the Industry 4.0 market is growing at a 19% CAGR and is expected to reach US$22 billion by 2032, with over two-thirds of manufacturers planning to adopt smart practices by 2025. Accelerated by the COVID-19 pandemic, the sector is embracing technologies like digital twins, cobots, edge computing, and 3D printing to boost efficiency, agility, and resilience. Government initiatives such as the PLI Scheme, Make in India 2.0, and Digital India, along with global partnerships, are further propelling adoption. As manufacturers strive for operational excellence, demand for intelligent, real-time, and automated solutions continues to surge.

Rationale for Investment

Market Opportunity

The Company is tapping into the global market opportunity in industrial digital transformation, with a focus on most factories over 95% that still operate with manual or fragmented digital processes. These factories represent a massive opportunity for operational optimization, and DesignX’s AI-powered platform directly addresses pain points like inefficiency, lack of visibility, and disconnected systems.

Industry Agnostic Solution

The Company’s solution is industry-agnostic, designed to work seamlessly across sectors like FMCG, automotive, pharmaceuticals, and electronics. Its modular, plug-and-play architecture allows it to integrate with any existing hardware or software stack, enabling manufacturers to digitize at their own pace without heavy capex.

Conclusion

By focusing on seamless integration, frontline empowerment, and scalable process digitization, the company addresses critical pain points that traditional IoT platforms often overlook. As the global push for smart manufacturing accelerates, DesignX’s Digital Factory Operating System (Df-OS) offers a compelling solution for manufacturers seeking agility, resilience, and operational excellence. Backed by growing industry demand, supportive government initiatives, and rapid technological adoption, DesignX is well-poised for significant growth and stands out as a frontrunner in India's emerging Industry 4.0 landscape.

Disclaimer — The article is made for informational purposes only and should not be regarded as an official opinion of any kind or a recommendation. It does not constitute an offer, solicitation or any invitation to public in general to invest in the stocks discussed. This article is confidential and privileged and is directed to and for the use of the addressee only. The recipient, if not the addressee, should not use this material if erroneously received, and access and use of this material in any manner by anyone other than the addressee is unauthorized. It shall not be photocopied, reproduced or distributed to others at any time. While reasonable endeavors have been made to present reliable data in the article, Rockstud Capital LLP does not guarantee the accuracy or completeness of the data in the article. Prospective readers are cautioned that any forward-looking statements are not predictions and may be subject to change without notice. No part of this material may be duplicated in any form and/or redistributed without Rockstud Capital LLP’s prior written consent.